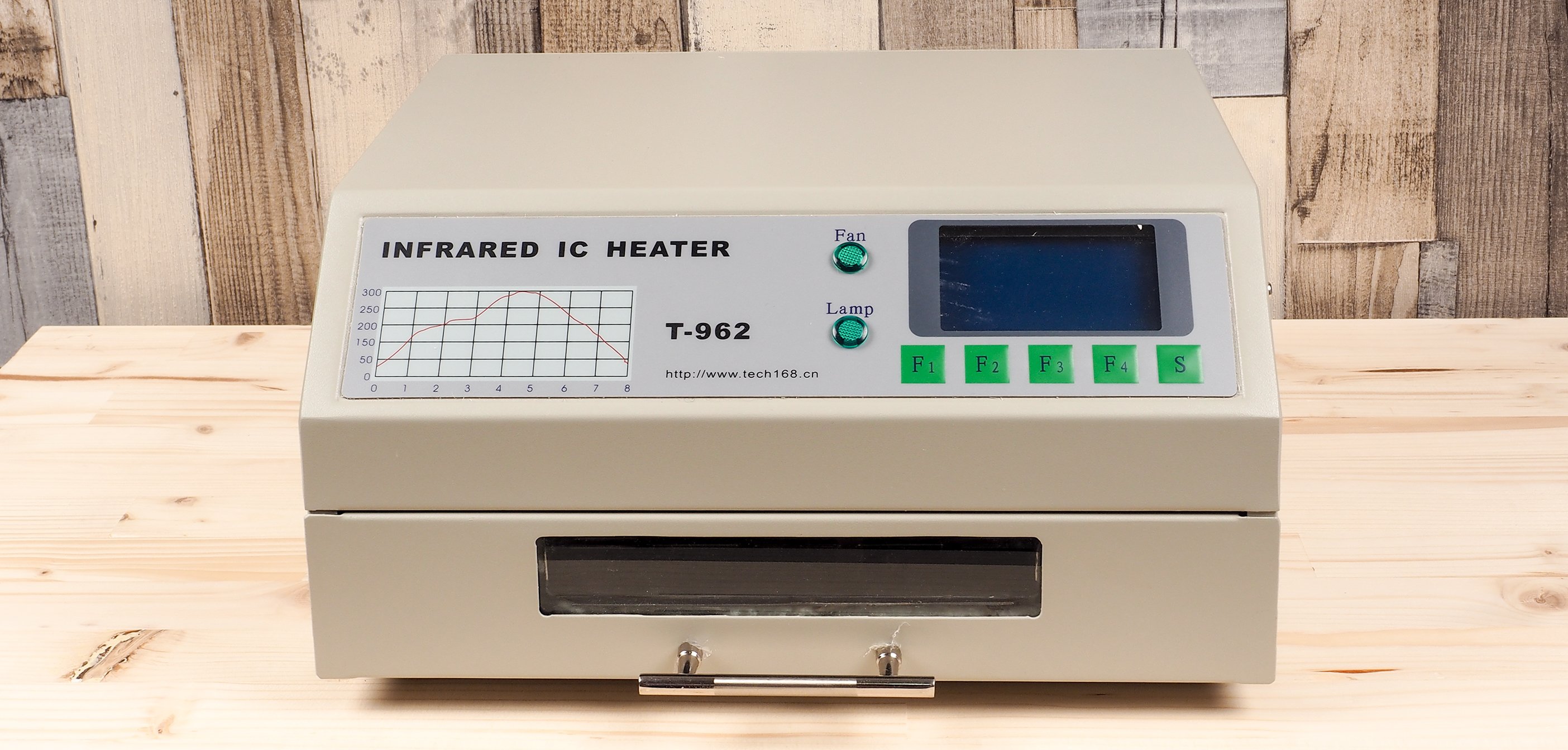

I’ve spent the last few days helping a fellow electronics engineer to solder a batch of PCBs, using a brand new T-962 reflow oven. How did this reflow oven perform? Is it worth the money? Let’s find out…

The reflow oven we had is brand new, albeit its manufacturing date looks to be somewhere in 2012. Hard to see, the writing is not clear. The serial number is also hard to read, you do more guessing than reading. Probably this particular oven has spent a lot of time in a warehouse before landing on my friend’s workbench.

Before starting to work, a few pics:

|

| T-962 reflow oven with tray opened |

|

| T-962 reflow oven – back side |

|

|

| T-962 reflow oven – upside down view |

The design is quite simple: two halogen tubes placed over the tray, and a big fan on the back side to blow cold air over the tray where the PCB's are placed to cook. The heated air exits through the slits beneath the tray.

Here’s the first thing that makes me say meh. The hot air is blown over the workbench surface, and I later found out that after running only one batch the workbench surface has become too hot to touch it!!! This is a major design flaw, and it’s quite dangerous to operate this reflow oven in a normal electronics lab setup. Ignore the air flow issue, and you can set your workspace on fire. If you a are lucky, you’ll get over with only burn marks on your workbench. Not that I know anyone who wishes that.

We “solved” this issue by placing a stack of ceramic tiles under the reflow oven, so there was a thermally insulating, non-flammable material between the workbench and the bottom of the oven. Even with this workaround, the first two tiles were very hot when we finished. We had to wait for one hour for the ceramic tiles to cool down before we were able to touch them.

I know, I’m a bit subjective there regarding how hot this thing becomes. I should have taken my thermal with me, but I didn’t expect such trouble from a brand-new piece of equipment.

Next, it was the smell. Both I and my friend have experience with reflow technology, and we are used with the fumes that come during the process, especially when using hobby-grade equipment. We know these fumes are dangerous, and we always take all the precautions required to reduce our exposure to soldering fumes.

However, this thing emitted a bad smell and much more fumes than we expected from the amount of solder paste used. Even in a well-ventilated room, with the windows wide open, the smell was overpowering. We ended up by starting the reflow process, and then we vacated the room until the fumes dissipated.

But what was causing all that smell and fume? It couldn’t be from the PCBs alone, so there must be another source of smell and fume inside the oven itself. So, after the oven cooled enough, we took a look inside. Here’s what we found:

|

| T-962 reflow oven – thermal insulation |

|

| T-962 reflow oven with case opened |

|

| T-962 reflow oven – is that painter's tape? |

|

| T-962 reflow oven – electronics detail |

There’s some sort of aluminum tape acting as a thermal insulator, plus a white tape that looks like masking tape to me. It seems that both materials were not designed to withstand high temperatures. The masking tape even started to peel and change its color in one corner.

Doing some research on the Internet I found this is a common problem with the T-962 oven. We found a whole wiki dedicated to T-962 problems and improvement suggestions. One suggestion was to replace the insulating tape with Kapton tape.

Unfortunately, there’s no easy fix for the air flow problem.

The only thing I would say is: don’t spend your money on this thing. There are better alternatives.

To me, even using a toaster oven for reflow work is safer. At least, the toaster oven doesn’t spill hot air over your workbench. And there are ready-made controllers that allow a regular toaster oven to perform reflow soldering. Or, why not, build your own controller for a fraction of that price. Anyway, you’ll be better, and safer.

Finally, a side note: it seems that there are plenty versions of this oven, released under other trademarks (such as ATTEN AT-R3028). Those clones might perform better, but there’s a good chance they have the same issues as the T-962 oven.

0 Comments